Both 2D or 3D model drawings are welcomed, especially in .dwg, .prt, and/or .igs

formats. Other than the above dimensional information, it would be helpful for us to

fabricate the tool if the following information will be provided in the drawing,

† Keypad / switch colors † Actuation force † Snap ratio

† Contact resistance specs † Material specs † Graphic & its color(s)

† Coating requirement † Surface abrasion spec

General Glossy or Matt Coating

Natural finished silicone rubber product usually have a“sticky” or “frictional” feeling on its surface. To eliminate this feeling or to provide a protective layer on the printed graphics, we could apply a silicone based painting onto the product. After applying the coating, the product surface will leave a smooth and soft feeling. These coatings can either be in glossy or matt finished.

Glossy or Matt PU Coating

For some product, which surfaces require a very high anti-abrasion ability, PU coating is recommended. This type of coating gives a harder and smoother feeling, comparing to the previous mentioned general coating, on the product surfaces.

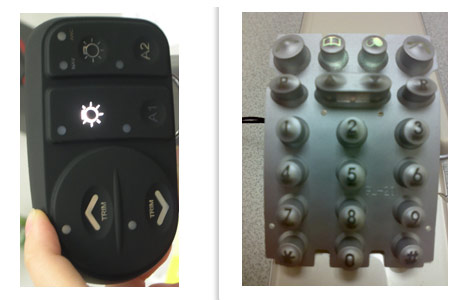

Epoxy Key-top potting

A crystal clear hard top could be applied to the key-tops of a silicone product. The normal thickness for this epoxy layer is 1.0 ~ 2.0mm. However, there is certain limitation on the geometric shape of the applied surface. Since the epoxy material is in molten form before it is cured to solidified, the applied surface should not be in a large inclination angle or the curvature should not be too convex.

Laser Etching

Graphics can also be laser etched onto the product surface to enhance the “back-lighting” effect, which is commonly applied to varieties of telecom products.